| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : ZW

Model Number : forged ball,grinding media ball

Certification : ISO9001:2008

Place of Origin : Jinan city,Shandong province,China

MOQ : 1 tons

Price : Negotiable

Supply Ability : Annual output 80000 tons

Delivery Time : 3 days after order confirmation

Packaging Details : container bags ,steel drum

Hsc : 73261100

Heat Treatment : Quenching and Tempering

Impact Toughness : ≥12 J/cm2

Diameter Tolerance : +1mm,-1mm

Leading Time : According to the contract

Surface Hardness : ≥60 HRC

Key Word : grinding media ball

Nominal Diameter : 25mm-140mm

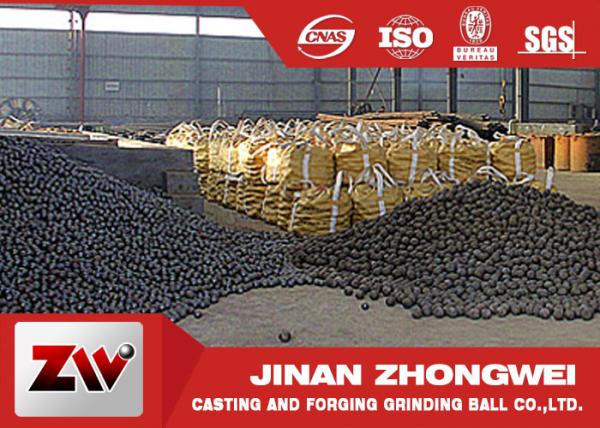

Certified Quality Cast Steel Balls Industrial Use Grinding Media Cement Mining Low Breaking Rate

Grinding steel balls are a main tool for grinding materials, usually used in ball mills. Grinding steel balls produce abrasive effects through collision and friction with the materials, thereby achieving the grinding effect of the materials

Forged Ball Details:

Forged steel balls are obtained by heating the metal to a suitable temperature, applying pressure to the metal blank by forging, causing it to undergo plastic deformation to obtain steel balls with certain mechanical properties, shapes and sizes.

| Material | Chemical Elements | |||||

| C | Si | Mn | P/S | Cr | Hardness (HRC) | |

| 45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | <0.035 | <0.25 | 60-65 |

| 60MN | 0.55-0.65 | 0.17-0.37 | 0.7-1.0 | <0.04 | <0.25 | 58-63 |

| B2 | 0.72-0.85 | 0.17-0.37 | 0.7-1.0 | <0.04 | 0.4-0.6 | 55-58 |

| B3 | 0.58-0.66 | 1.3-1.9 | 0.65-0.8 | <0.025 | 0.7-0.9 | 56-65 |

| B6 | 0.97-1.03 | 0.2-0.3 | 1.0-1.1 | <0.025 | 0.5-0.6 | 61-65 |

|

Material

|

25mm-50mm HRC |

60mm-90mm HRC |

100mm-125mm HRC

| 130-150mm HRC | ||||

| Surface | Core | Surface | Core | Surface | Core | Surface | Core | |

| C45 | 55-58 | 55-58 | 50-68 | 23-30 | 48-52 | 22-26 | 48-52 | 22-25 |

| 60Mn | 58-62 | 55-60 | 58-62 | 30-36 | 57-61 | 26-32 | 57-61 | 26-30 |

| B2 | 60-64 | 58-64 | 57-64 | 45-60 | 55-60 | 38-48 | 55-60 | 38-42 |

| B3 | 62-65 | 60-65 | 60-65 | 58-65 | 56-65 | 50-62 | 56-63 | 50-55 |

| B6 | 62-65 | 60-65 | 61-65 | 58-65 | 60-63 | 50-62 | 61-63 | 50-55 |

Casting Ball

Casting steel balls are made by heating and melting scrap steel, scrap iron and other waste furnace materials in a medium frequency electric furnace, and adding appropriate amounts of precious metal alloys (such as ferrochrome, ferromanganese, ferrovanadium, etc.) during the melting process to temper the chemical composition. When the molten iron temperature reaches above 1550℃ and meets the process requirements, the qualified molten iron is poured into the steel ball mold, and the spherical iron alloy wear-resistant body is made through quenching, tempering, testing and packaging.

1) Traditional Forged

Raw material →Cutting →Heating → Water quenching → Tempering

2) Auto Hot Rolling

Raw material →Hot Rolling Mill → Water Quenching → Tempering

3) Casting

Raw material preparation →Smelting→ Pouring→Cooling and demoulding→Heat treatment and inspection

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

Q2. Do you have any MOQ limit for the order?

A: 1ton MOQ.

Q3. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

|

|

Certified Quality Cast Steel Balls Industrial Use Grinding Media Cement Mining Low Breaking Rate Images |